Update to the below: I wanted to recast this mold, but did not have time this week. I designed and 3D printed the top of the maze mold so I could recast the candy. I would still like to do this in the future.

++++++++++++++

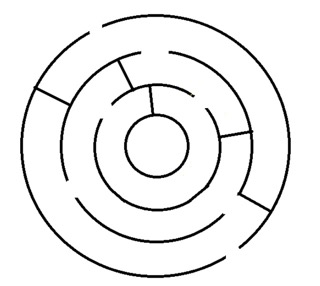

For this week's project, I wanted to make some sort of candy that could also double as a game. I decided to design a candy mold in the shape of a maze.

In the spirit of fall, I went with making maple sugar candy (and, conveniently, I was in Montreal and could pick up plenty of syrup).

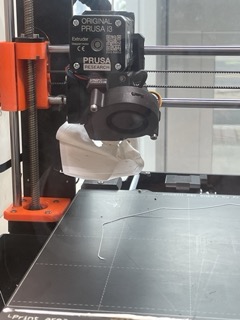

I worked for a long time to try design a the maze in Fusion 360, but I stopped because it was taking hours (I'm still learning CAD). So I borrowed a design for two mazes online, which I 3D printed. The first print failed, not because the design was bad but because something happened with the machine. It's possible the plate was dirty or there was another issue. I learned to make sure to watch the printer at the beginning to ensure the object's base sticks.

Finally, two printed:

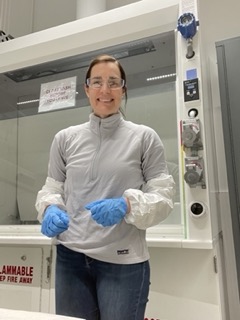

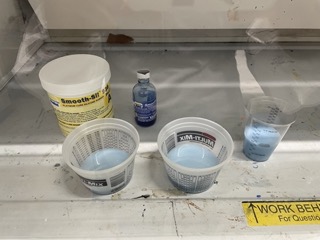

Next, I chose Smooth-Sil 939 to create the mold, which is a food-safe option. I donned all the safety gear and mixed the silicone under the hood. The pot time for the silicone was 1 hour. The cure time was 16 hours.

The next day, I was able to remove one of the two molds. The second was stuck--I tried using heat, but was unable to remove it.

Now, the fun part: making maple sugar candy in Montreal.

While still soft, I put the maple candy into the mold and left it overnight. To my dismay, it crumbled when I removed it. This mold was too small and the walls of the maze were too thin for it to work for this type of candy. The other maze (see the white 3D print pictured above) would have worked better, but alas...it was still delicious.